State of market

California has an enormous need to bring new energy storage capacity on the grid, especially for commercial and industrial (C&I) energy users. As you’ll see below, the project pipeline reflects the need. However, procurements and interconnections are not keeping up with demand.

Pipeline

37,040 MW solar+storage projects in the Cal ISO interconnection queue, as of June 2021

15,115 MW stand-alone energy storage projects in the Cal ISO queue

Procurements

4,189 MW energy storage procured, according to California Energy Storage Alliance

250 MW behind-the-meter energy storage procured

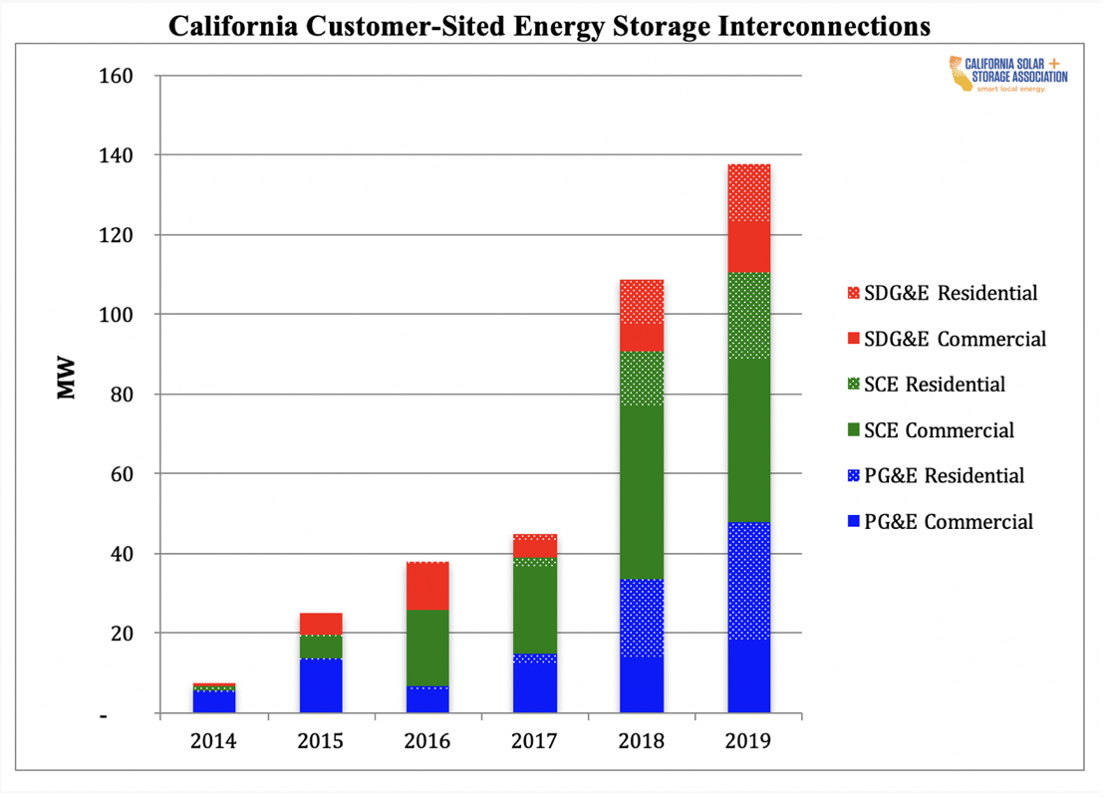

Interconnections

Key barriers to growth

What’s standing in the way of market growth for C&I energy storage in California? A little bit of everything. Although California is a market leader, it takes longer to complete project permitting than in other states, like Florida and Nevada. Interconnection costs are higher, too. One way to make utility rates more energy storage-friendly would be to shift from monthly demand charges to daily demand charges, as described below.

Permitting

Median inspection times for on-site commercial-scale energy projects in California are slow, according to solar data collected by the National Renewable Energy Laboratory. The wait time tends to be 19.5 days. This contributes to a wait time of nearly 3 months overall for permitting, interconnection, and inspection. California can speed up inspection times.

Interconnection

Many utilities in California and around the country require no fee to apply for interconnection for on-site energy projects. The investor-owned utilities in California are different. PG&E customers pay an interconnection fee of $145. San Diego Gas & Electric customers pay a $132 fee. Southern California Edison customers pay a $75 fee. California can eliminate interconnection fees.

Utility rate design

In November 2019, PG&E introduced commercial rate tariffs with daily demand charges, becoming the first utility in California to do so, according to the California Solar + Storage Association. Instead of collecting demand charges based on the highest single interval of demand in the monthly billing cycle, PG&E’s new approach assesses charges according to the highest level of demand within set periods each day. For system operators, this offsets the risk of unpredictable demand charges and the need for risk mitigation.

When PG&E introduced daily demand charges, California regulators limited participation to 50 MW of storage for each rate tariff offering daily demand charges, or 150 MW overall. Regulators should make daily demand charges the norm in California and make sure they are accessible to commercial customers throughout the state.

Solution

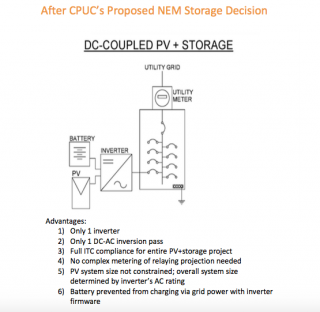

In 2019, California regulators gave operators of solar-plus-storage projects an opportunity for the first time to export battery power onto the grid and receive net energy metering (NEM) credits for the output. NEM for storage has huge implications for the market, as we explained in a recent blog post.

- NEM for storage eliminates the need for expensive meters, relays, and switchgear.

- It simplifies design for solar-plus-storage systems.

- And it builds consensus around the value of distributed energy resources at a time when legislators and utilities are pushing hard to undercut NEM for solar.

Featured project

For a Riverside County office building, SepiSolar Chief Electrical Engineer Richard Dobbins designed a 694.9 kW array of solar canopies to cover the parking lot and an 87 kW, 193.5 kWh battery energy storage system for an enclosure at the edge of the property. See our solar and storage design examples page to download the project’s site plan, three-line diagram, parts list and more.

Have a C&I solar project of your own?

If you have a C&I solar project and need some design and engineering expertise, don’t hesitate to contact us for help. Simply click below, provide some details about your project and we will follow up promptly to discuss it with you.

On Oct. 5, 2018, the California Public Utilities Commission (CPUC) issued a proposed decision to modify CPUC Decision 14-05-033, the NEM tariff policy for solar and energy storage. Once approved, the change will allow DC-coupled energy storage systems to become eligible for NEM without the need for thousands of dollars in extra hardware costs and burdensome verifications required by California utilities and the IRS for AC-coupled energy storage systems.

On Oct. 5, 2018, the California Public Utilities Commission (CPUC) issued a proposed decision to modify CPUC Decision 14-05-033, the NEM tariff policy for solar and energy storage. Once approved, the change will allow DC-coupled energy storage systems to become eligible for NEM without the need for thousands of dollars in extra hardware costs and burdensome verifications required by California utilities and the IRS for AC-coupled energy storage systems.