The California Public Utilities Commission (CPUC) recently passed the NEM 3.0 bill, which brings significant changes to the state’s net metering policy compared to the previous NEM 2.0. As a homeowner or business owner interested in solar, it’s essential to understand the differences between the two policies and the new opportunities they present. In this blog post, we will explore the key differences between NEM 2.0 and NEM 3.0, and how to effectively sell solar panel systems to maximize savings under the new policy.

NEM 2.0 vs. NEM 3.0: Key Differences

The Value of Export Rates

Under NEM 2.0, customers received a full retail rate for any excess electricity they exported to the grid, allowing for a faster return on investment (ROI) in solar energy systems. With NEM 3.0, export rates have been reduced by about 75%, meaning customers will receive less money for the energy they sell back to their utility company. As a result, it may take longer for homeowners to recoup their investment in solar energy.

Instantaneous Netting

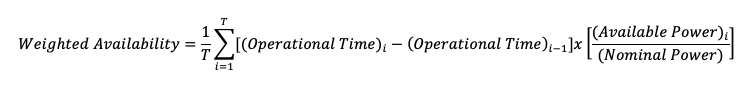

NEM 2.0 calculated electricity rates every hour based on a user’s net generation and usage during that hour, which was more favorable for solar customers. NEM 3.0 introduces instantaneous netting (or rapid cycling), allowing meters to communicate in real-time instead of hourly. This change may result in less financial benefit for solar customers and more complex calculations.

Grid Participation Charge

NEM 3.0 introduces a “Mandatory Grid Participation Charge” that requires all participants to pay a fee for using the network’s resources and services. Solar customers can expect to pay an extra $8 charge per kilowatt (kW) of solar power capacity, resulting in an average additional cost of $48 per month for homeowners, further reducing solar energy savings.

Strategies for Maximizing Solar Savings under NEM-3.0

Emphasize long-term savings and environmental benefits

Despite the policy changes, solar energy systems still offer significant long-term savings on electricity bills and environmental benefits. Communicate the long-term advantages and the positive environmental impact of solar energy investments, such as reducing greenhouse gas emissions and conserving natural resources.

Promote solar+storage solutions

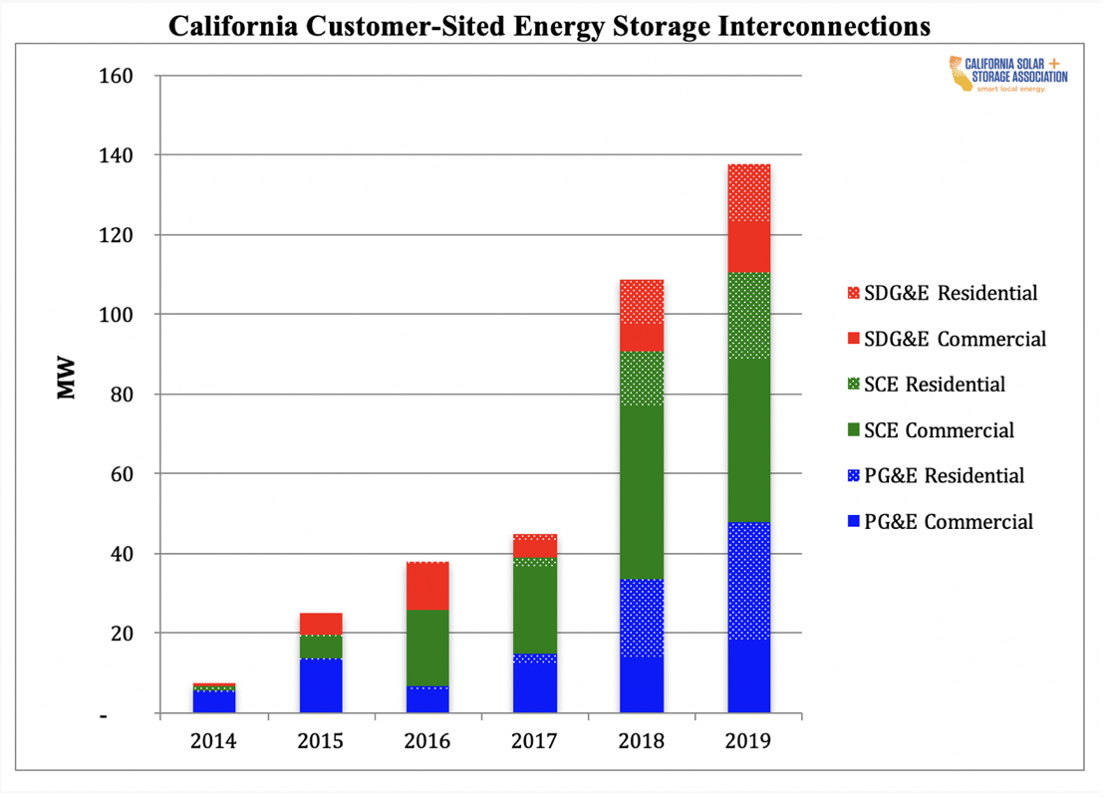

With NEM-3.0 encouraging battery storage adoption, solar providers can promote solar+storage solutions to maximize self-consumption, take advantage of time-of-use (TOU) rates, and provide backup power during outages. By incorporating battery storage, customers can offset the reduced export rates and increased grid participation charges under NEM 3.0, achieving substantial long-term savings.

Offer tailored solar+storage solutions

With NEM-3.0 encouraging battery storage adoption, solar providers can promote solar+storage solutions to maximize self-consumption, take advantage of time-of-use (TOU) rates, and provide backup power during outages. By incorporating battery storage, customers can offset the reduced export rates and increased grid participation charges under NEM 3.0, achieving substantial long-term savings.

Leverage available incentives and financing options

Despite the higher initial costs of solar+storage systems, customers can still take advantage of various incentives, such as the federal solar Investment Tax Credit (ITC), California’s Self-Generation Incentive Program (SGIP), and other state and local incentives. Additionally, offering flexible financing options like solar loans, leases, and power purchase agreements (PPAs) can make these systems more accessible to a wider range of customers.

Build trust through transparency and education

Establish credibility with your customers by being transparent about the costs, savings, and potential challenges associated with solar+storage installations under NEM-3.0. Provide honest and accurate information, and educate your customers about how solar+storage systems can help them maximize their savings and reduce their environmental impact. By fostering long-lasting relationships built on trust and transparency, you will position yourself as a valuable partner in their clean energy journey.

Conclusion: Learn to thrive in California’s dynamic solar energy market

Although the NEM 3.0 policy brings significant changes to California’s net metering landscape, there are still opportunities for solar providers to help customers maximize their savings. By understanding the key differences between NEM 2.0 and NEM 3.0, promoting solar+storage solutions, offering tailored recommendations, and leveraging available incentives, you can help your customers make informed decisions and achieve long-term savings. By adapting your sales strategies and focusing on the benefits of solar+storage, you can continue to thrive in California’s dynamic solar energy market.