This post was written by Josh Weiner, Solar Expert Witness & Solar Engineering Expert. Mr. Weiner has been at the forefront of the solar energy industry for over 20 years and is an industry leader on solar-plus-storage engineering & design. Josh’s expertise spans both in-front of and behind-the-meter initiatives including residential, commercial, utility, grid-scale, and ev charging solar and storage applications.

Lithium battery safety is not rocket science. Manufacturers with a robust set of production data can show customers success rates for their batteries and the conditions that cause batteries to fail. The problem is that very little safety data is accessible to most buyers or the public.

Buyers will always have to decide for themselves how much risk they are willing to tolerate. Some source batteries from a selective group of original equipment manufacturers (OEMs) and pay a premium to avert risks associated with the lowest-priced batteries. But many buyers are operating in the dark, lacking the safety data they would need to make an informed decision.

Consequently, the energy storage industry in its brief history has already witnessed dangerous and damaging lithium battery safety incidents, including the April 19 fire at Arizona Public Service’s McMicken Energy Storage facility. Other notable incidents include a lithium battery fire and subsequent battery malfunction that led the Federal Aviation Administration in 2013 to ground Boeing’s entire 787 Dreamliner fleet. The next lithium battery fire can happen almost anywhere, anytime.

To safeguard against fire risks, ask lithium battery makers the questions about cell production and testing in this post. Battery buyers don’t have to wait for technology development or new regulations. They can bring about a new safety standard by demanding better safety data and buying lithium batteries only from OEMs that make the data available.

Questions to ask about cell production

Some online shoppers go to commerce platforms like Kickstarter for innovative products and products that may be available at a significant discount from an upstart manufacturer. When sourcing lithium batteries, you want to take the opposite approach. Instead of pursuing innovative products, look for proven products that have a long track record of consistent production. Instead of hunting for discounts from unknown suppliers, expect to pay fair value for a product that has completed a rigorous safety analysis and achieved an exceptionally low failure rate.

How many battery cells and battery packs does your supplier produce each year?

One lithium cell represents one data point. The more cells you produce, the more data you have. As such, the highest-volume producers have the most data on performance, thermal runaway, and failure.

For this reason, an OEM producing 10 million cells per year should have a better understanding of cell safety and performance. Large-volume manufacturers have probably seen every possible failure occur many times. By the same token, a small-volume manufacturer needs more time to analyze and understand cell failure. Buying cells from small-volume manufacturers may carry more risk.

What changes have been made to the battery cell and battery pack production process?

A consistent manufacturing process yields predictable safety and performance results. It’s plain to see that different cell materials bring about different cells. But different production equipment can affect safety characteristics just as much. Even if the materials and equipment stay the same, a manufacturer that relocates production may alter a host of environmental conditions and other variables that affect results. Changes in relative humidity, temperature range, and impurities in the air can impact safety characteristics of lithium cells. Differences in quality control and other processes introduced by a new manufacturing technician crew can also have an effect. All these changes should be understood and quantified in a prudent lithium battery safety analysis.

How does your supplier handle material acceptance and storage?

Even if everything goes right during the manufacturing process, pre-production material acceptance and storage can affect lithium battery safety. About five years ago, a global supplier of solar inverters experienced a series of product failures after electronic circuit boards had been stored in the wrong warehouse and exposed to moisture. Once product assembly was complete and the inverters were energized, a short circuit on the boards caused a fire and led to quite a bit of property damage. While moisture can also affect battery cell safety, so can other environmental conditions, such as air impurities and particulate matter.

It’s not easy to perform a safety analysis that identifies failure points for battery cells. To test how moisture affects safety, you would have to take identical cells and store one of the cell materials in an environment that gets wetter in small increments until you find a statistically relevant number of failures. Then you would have to repeat the process with incremental changes in temperature, dust, and other variables. Testing would require a lot of cells, a lot of minor changes in cell processing, a lot of time, and a lot of analysis. And it would all have to be done without vastly increasing cell production costs.

What are the failure rates for your supplier’s battery cells and battery packs?

In the absence of industry-wide standards, contractors seeking assurances about product safety have their work cut out for them. First, they have to request failure rates and analysis from each of their suppliers. Then the manufacturers must provide the data. Next comes the subjective test. If the contractor feels comfortable with the risk, he or she can decide if the battery quality is adequate. Different contractors have different tolerance levels for quality. A contractor who installs one small system per year may not place a great deal of emphasis on quality. The chances of failure are small. However, contractors installing many large systems must pay more attention to quality. Their businesses depend on the successful operation of a much larger population of cells.

Consider an OEM with a 99.98 percent success rate for battery cells in the first three years of operation. That translates to a 0.02 percent failure rate. If a contractor installs 1,000,000 cells per year, the contractor can expect 600 cells to fail. [Multiply failure rate (0.0002) x annual production (1,000,000) x number of years (3).] This might be an unacceptable level of risk. On the other hand, if a contractor installs 10,000 cells per year, the contractor can expect 6 cells to fail. This level of risk might be no big deal, so long as those cell failures don’t propagate to the entire pack or the entire storage system.

Questions to ask about cell testing

We all know not to leave a fireplace unattended or a gas oven running when nobody’s home. We understand that doing so introduces a serious risk of fire. But how many people know the temperature threshold that is likely to cause a lithium battery to catch fire or explode? Before procuring lithium batteries, especially those that will be sited at a building where people live or work, be sure to understand the conditions that create lithium battery safety hazards. Safety hazards that start in a single battery cell can quickly spread to the battery pack and the entire energy storage system.

What are your supplier’s battery cell thermal runaway characteristics?

It’s important to understand how a battery cell responds to the conditions that can initiate a fire or an explosion. There are many ways to test lithium cells for these conditions. Some examples are the top nail test, where a nail of standard size is driven with standard force into the top of the battery, and the side nail test, where the same procedure is carried out with a battery lying on its side.

Other tests include the fast heat test, where a battery inside a control chamber is exposed to a rapid temperature increase; the slow heat test, where a battery is exposed to a slow temperature increase, and the overcharge test, where a fully charged battery stays connected to a power source and is continually charged.

What is the probability of thermal runaway for your battery cells?

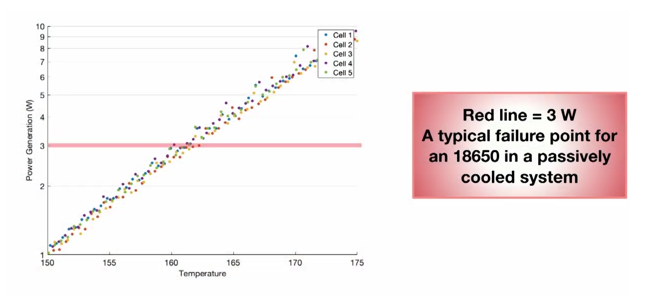

With test results in hand, you can make reasonable predictions about how a battery will perform according to design specifications. Graph 1 shows how increased temperature leads to thermal runaway. While all five cells exhibit similar power generation as temperature increases, there is a notable difference in how close each cell comes to the failure point represented by the horizontal red line at 160°.

Graph 1

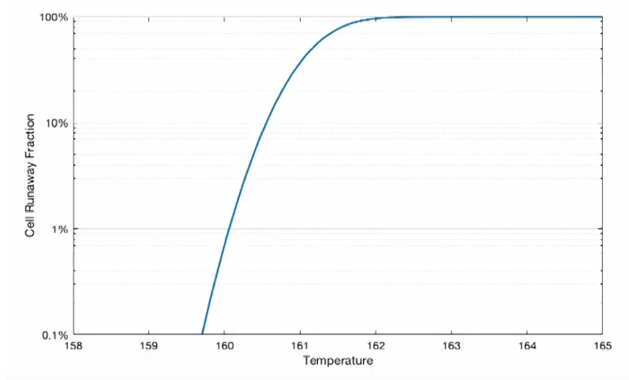

Graph 2 shows how constant temperature over time leads to thermal runaway. The battery cell depicted by this graph remains at very low risk of thermal runaway when temperature is held constant at 159°. But a 1° increase in constant temperature vastly increases the probability of thermal runaway. A 2° increase makes thermal runaway a near certainty.

Graph 2

One of the challenges when characterizing lithium cell failure is calculating at what temperature and over what duration a cell fails. Because the answer is different for each cell, we need to see how different the answers are. What if one cell failed after two hours at 60°, another cell failed after 5 hours at 190°, and a third cell failed after 3 hours at 250°? This data would be difficult to characterize. It seems like almost every temperature is dangerous and could lead to cell failure.

Now what if the data looked more like this? Cell 1 fails after two hours at 160°, Cell 2 fails after two hours at 161°, and Cell 3 fails after 1.5 hours at 162°. This data suggests that thermal runaway is consistent and predictable. If we can find consistent results, we know when failures occur and how to prevent failure by designing systems for lithium battery safety.

How does thermal runaway spread from cell to cell?

This is really a two-part question. For starters, let’s look at how thermal energy from a failed lithium cell gets distributed across neighboring cells. Do all neighboring cells get the same amount of energy from the failed cell? Does one cell get all the energy while the others get none? Do two cells get 90 percent of the energy? Next, let’s look at how much stress an initiator cell applies on neighboring cells. If a failed cell exposes neighboring cells to temperatures up to 120°, the risk of cell-to-cell propagation is low. The risk is much higher if a cell failure has a magnitude of 180°. If energy is distributed unevenly, we would want to know the magnitude of stress for each of the neighboring cells.

What are the conditions that lead an entire battery pack to catch fire?

If cell-to-cell propagation extends to one or two neighboring cells and stops, failure of the whole battery pack or battery module is unlikely. If cell-to-cell propagation extends to hundreds of neighboring cells, it’s far more likely that the entire pack will burn. By understanding when battery packs catch on fire and start heating up the neighboring packs, the system designer can plan for fire detection and suppression systems as required by NFPA 855 and UL 9540A to kick in as a last line of defense.

What are the conditions that lead an entire energy storage system to catch fire?

If a fire containment system fails to contain a fire within the energy storage system enclosure, the charging infrastructure for the batteries may also catch on fire. (Think of a car catching on fire while being pumped with fuel at the gas station. Fire can spread to the gas pump, then the entire gas station.) Once the charging infrastructure is on fire, the entire property, including its occupants, are at risk. In sum, one battery cell failure can lead to the destruction of an entire building and the loss of life.

Demand lithium battery safety data

A safe battery is a well-documented battery. Test data helps engineers, system integrators, system owners, and regulators make smart, effective business decisions. While data doesn’t eliminate risk, it does inform us of the risk. Therefore, data empowers us to make decisions on how to manage, contain, suppress, mitigate, or ignore it. By putting appropriate measures in place, we can reduce risk to an industry-acceptable level. Without test data, a battery might operate safely today, but we don’t know why. Then if conditions change and the battery is no longer safe, we won’t know how to mitigate the risk.

The industry can expect a steady supply of safe lithium batteries as soon as buyers make purchasing decisions conditional on access to safety data. There are many safe batteries on the market. But there are many more cheap, risky batteries on the market. The simple solution is to buy safe batteries—which might mean accepting a higher price.

Contractors should request data from OEMs or look for third-party evaluations from independent engineering (IE) reports or independent test laboratories. The data is not publicly available, or hard to find, which is a serious problem. UL, the “gold standard” in product safety, even has trouble gaining access to this sort of data. So one requirement in the UL 9540 standard is to capture thermal runaway data, even for batteries that pass all the tests. In other words, when a lithium battery goes for the UL 9540 test, the test lab will force the battery into thermal runaway and then document the results to help characterize lithium cell failure.