This post was written by Josh Weiner, Solar Expert Witness & Solar Engineering Expert. Mr. Weiner has been at the forefront of the solar industry for over 20 years and is an industry leader on solar-plus-storage engineering & design. Josh’s expertise spans both in-front of and behind-the-meter initiatives including residential, commercial, utility, grid-scale, and ev charging solar and storage applications.

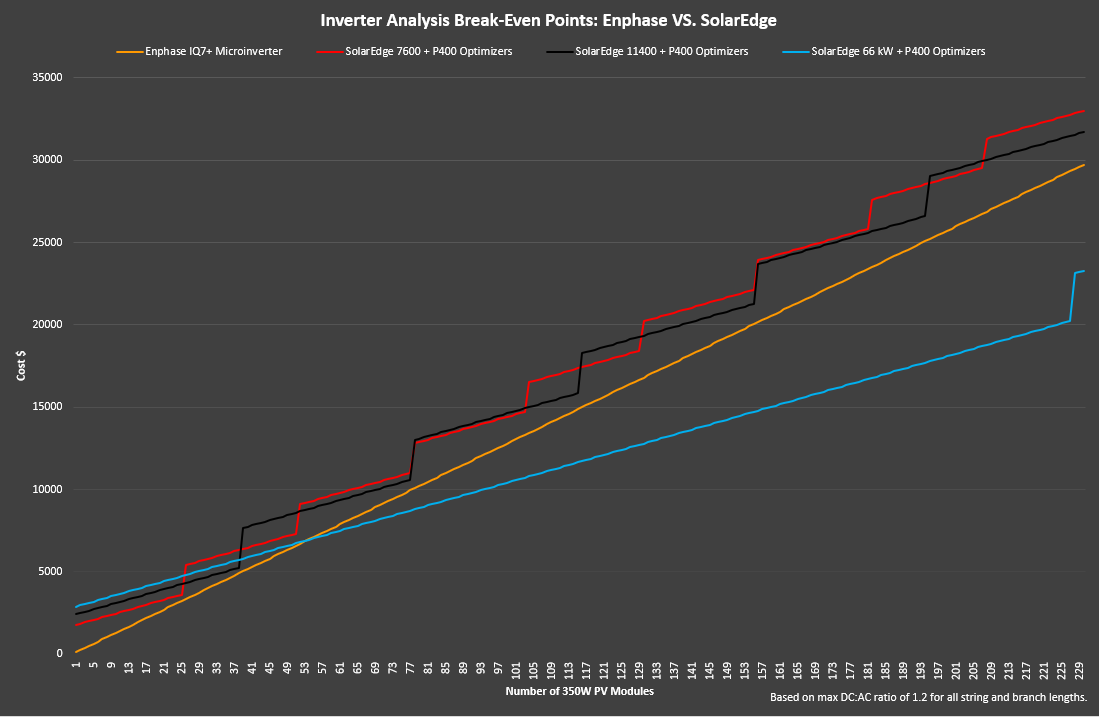

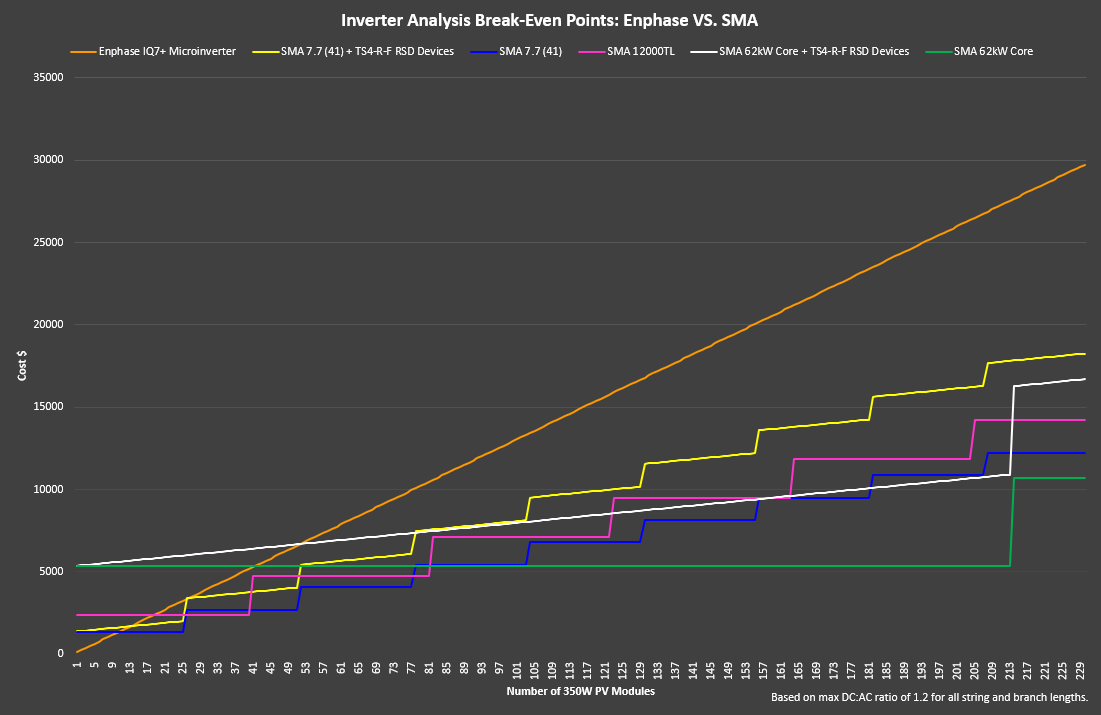

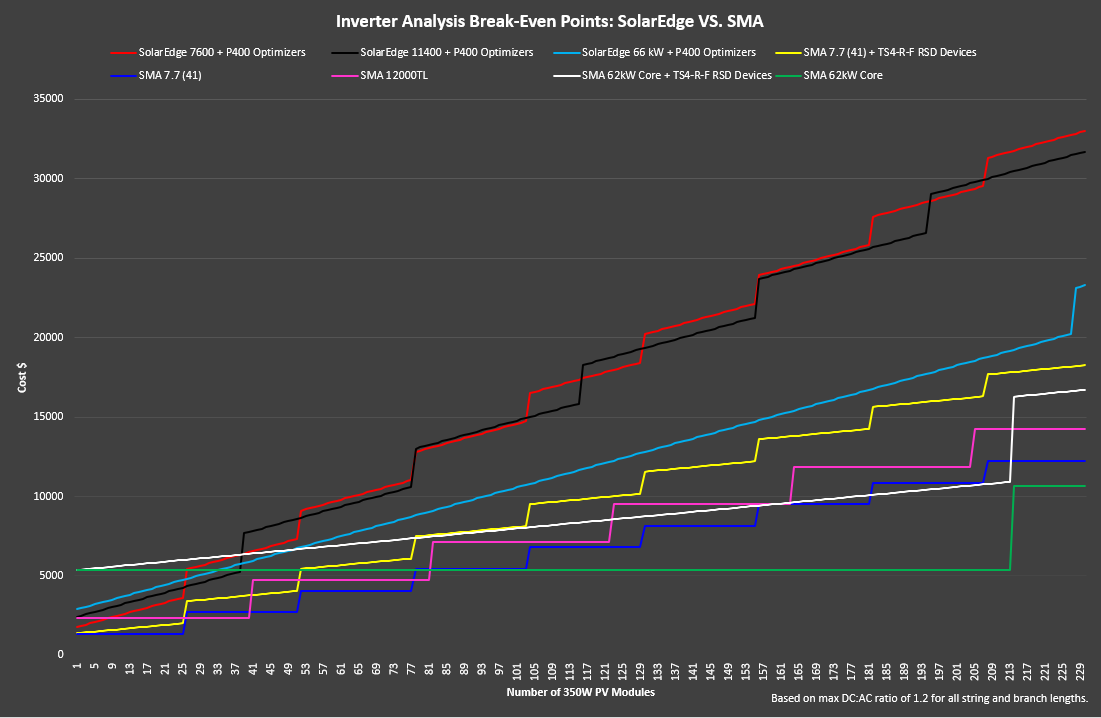

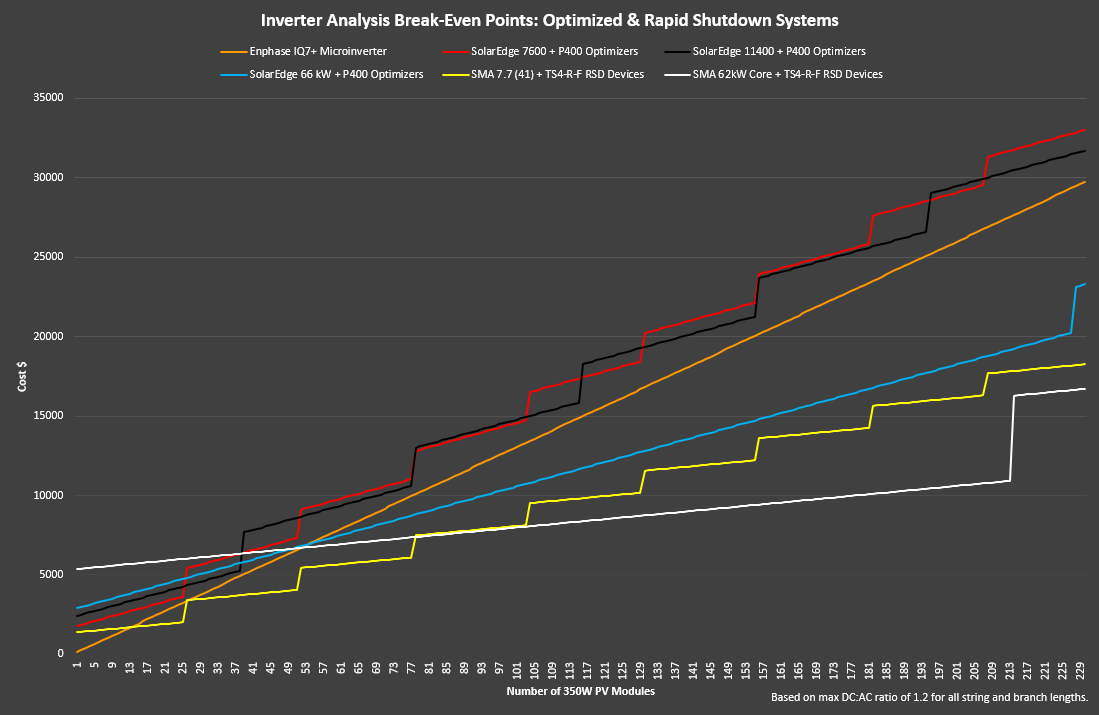

Not all inverters are created equal, or equally cost-efficient, when designing residential and commercial solar projects. We see contractors choosing between microinverters and various string inverters, but not always knowing when you might end up paying a price premium. Sometimes a sizable one.

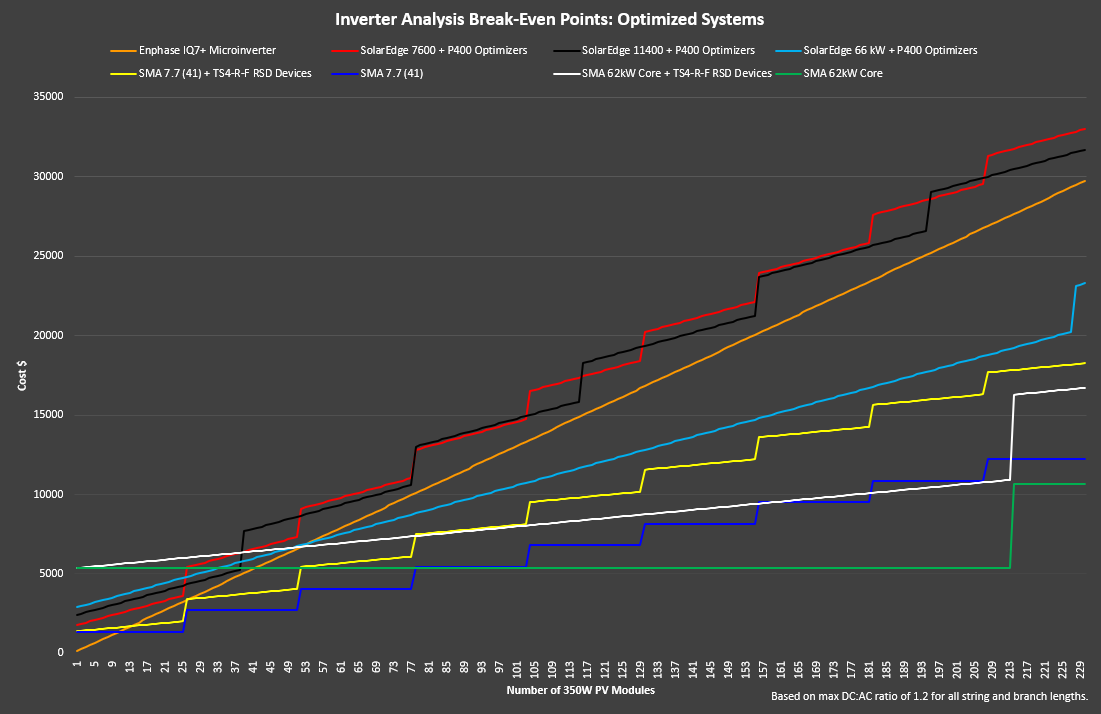

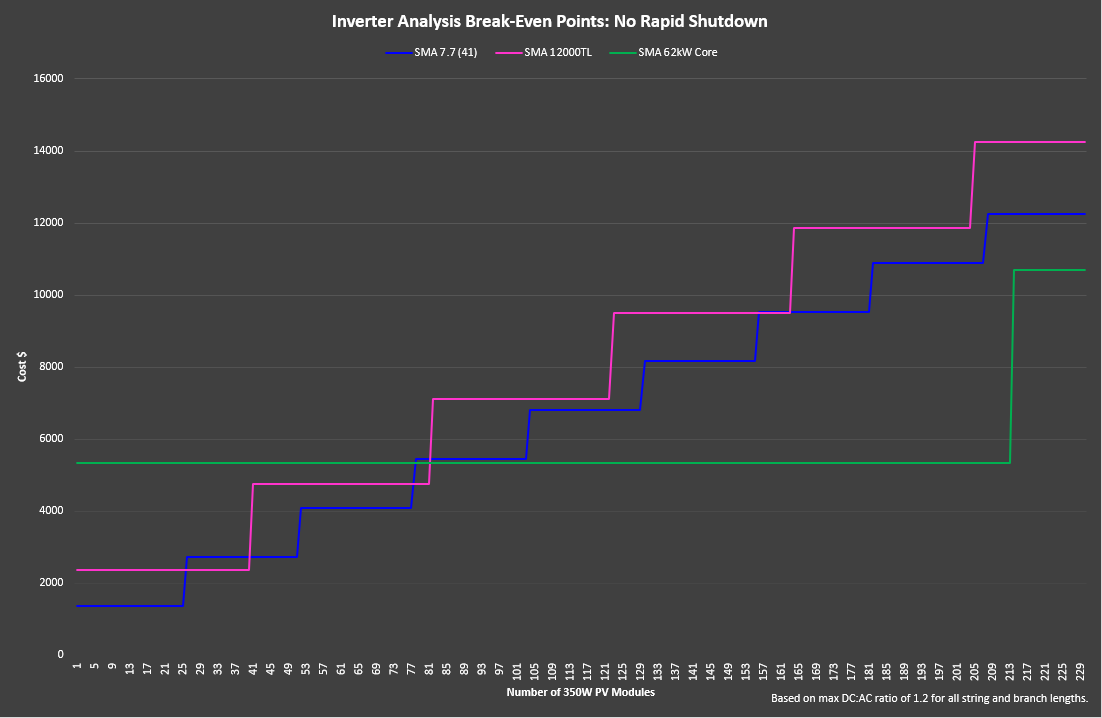

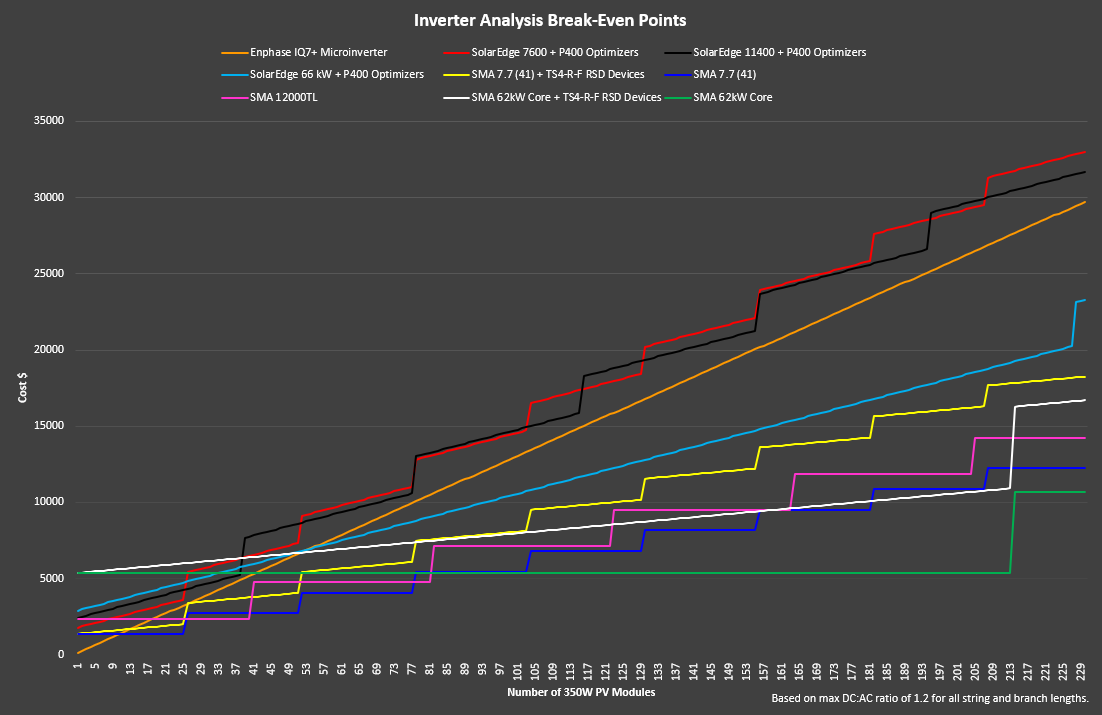

We recently worked on some system designs that led us to take a closer look at breakeven points for seven well known inverters.

- Enphase IQ7+

- SolarEdge SE7600H

- SolarEdge SE11400H

- SolarEdge SE-66.6K

- SMA SunnyBoy 7.7

- SMA TriPower 12000TL

- SMA TriPower CORE1 62

One commercial project used 50 Enphase IQ7+ microinverters. There’s no question the contractor could have found string inverters at a lower cost. Could the additional cost be offset by a lower-cost installation? Or more energy over the life of the system? That depends in part on how far the project has gone past the inverter breakeven point.

Tradeoffs are part of solar design. But it would help to know based on current market prices where one inverter system becomes more expensive than another.

Equipment costs

It’s time to run some numbers. Let’s find out what size system, and how many modules, it takes for contractors to favor SMA, SolarEdge or Enphase based on cost alone. I chose the LG LG350N1C-V5 (350 Watt) module as the control for all inverter options. Why? Its popularity and feasibility for residential and commercial projects.

Here are the key takeaways. Read on for more details.

- For systems with 11 modules or more, the SMA 7.7 has lower cost than the Enphase IQ7+.

- With 14 modules or more, SMA’s 7.7 with TS4-R-F Rapid Shutdown Devices (RSD) devices becomes less expensive than the Enphase IQ7+.

- 19 modules or more? The SMA 12000TL without optimizers or RSD devices becomes cheaper than Enphase’s IQ7+.

- With 42 modules or more, SMA’s TriPower CORE1 62 has lower cost than the Enphase IQ7+.

- For systems with 52 modules or more, SMA’s TriPower CORE1 62 becomes less expensive than the Enphase IQ7+.

- With 54 modules or more, SolarEdge’s SE-66.6K becomes cheaper than the Enphase IQ7+.

- The Enphase IQ7+ has lower cost than the SolarEdge SE7600 with optimizers and SolarEdge’s SE11400H.

How I crunched the numbers

I found all prices on thepowerstore.com except the combiner panel for the Enphase IQ7+. That one I priced at homedepot.com.

Enphase uses one IQ7+ microinverter per module and one AC Combiner Box. SolarEdge uses as many string inverters as needed based on the combined DC output of the module array, plus one power optimizer per module. SMA uses as many string inverters as needed based on the combined DC output of the modules.

The SMA SunnyBoy and TriPower CORE1 series inverters have SMA’s proprietary ShadeFix technology. ShadeFix, based on the OptiTrack software released in 2010, allows current to bypass shaded areas of solar modules. This keeps current high for non-shaded areas.

SMA ShadeFix is built into the inverter. Optimization gains are comparable to SolarEdge optimizers and Enphase microinverters in zero-to-moderate shading with no additional components, keeping costs lower. However, in heavy shading, SolarEdge and Enphase have slightly better optimization gains. Consider cost, ease of installation, shading, and other factors when choosing an inverter for any system.

SMA inverters used to require rapid shutdown devices under each module, plus a CCA datalogger, safety control unit, and communication gateway. This added cost. SMA ShadeFix has simplified and reduced the cost of systems with optimization.

Also worth mentioning, SMA no longer manufactures the TriPower 12000TL. It’s only available from suppliers who still have units in stock. SMA’s TriPower 12000TL does not have ShadeFix. Nor the option to add optimization. I added it primarily as a direct comparison to the SolarEdge SE 11400H.

Plotting equipment costs and module count in a line graph, you can see Enphase has the lowest cost in systems with 10 or fewer modules. It has one of the highest costs with 55 modules or more.

Price list

| Company | Equipment | Cost |

| Enphase | IQ7+ | 129 |

| 100A AC Combiner panel | 74 | |

| SolarEdge | SE7600HD | 1,706 |

| SolarEdge | SE11400H | 1,360 |

| SolarEdge | P400 Optimizers | 77 |

| SolarEdge | SE-66.6K | 2,822 |

| SMA | SunnyBoy 7.7 (41) | 1,360 |

| SMA | TriPower 12000TL | 2,375 |

| SMA | TriPower CORE1 62 | 5,343 |

| SMA | TS4-R-F RSD Devices | 26 |

The takeaway: size matters. The larger the project, the less cost-effective microinverters become. Cost, however, is not the only factor.

Data for informed decisions

Contractors might prefer how modules preinstalled with microinverters can speed up and simplify installation. Other benefits include monitoring, panel-level optimization, safety, and warranties up to 25 years.

Contractors might dislike microinverters because they limit the number of modules on a string. They also have worse voltage drop than a string inverter system of similar size.

At the same time, the industry leaders, including these three, are all moving toward integrated systems with storage and energy management. Looking ahead, how might decisions today affect future upgrades and system performance?

The point is not to suggest one inverter system is better than another for any one system design. Consider many variables.

First, set the top priorities for a project—cost, performance, ease of installation, resilience. Then figure out what kind of inverter will best support short- and long-term goals.

Different projects will pencil out differently. But comparing inverter costs can help you and your customers make good decisions for your projects.